Tratamento térmico HTST e UHT com uma quantidade mínima de produto

O tratamento térmico proporciona a inativação microbiana e enzimática para ajudar a prolongar o período de conservação de certos produtos alimentares e bebidas para garantir a segurança alimentar. Contudo, este processo pode danificar as propriedades organoléticas do produto. Compreender porque esta situação ocorre já nas fases iniciais de formulação, bem como o seu impacto, pode reduzir o tempo de comercialização. No entanto, estas investigações podem revelar-se dispendiosas e extremamente demoradas.

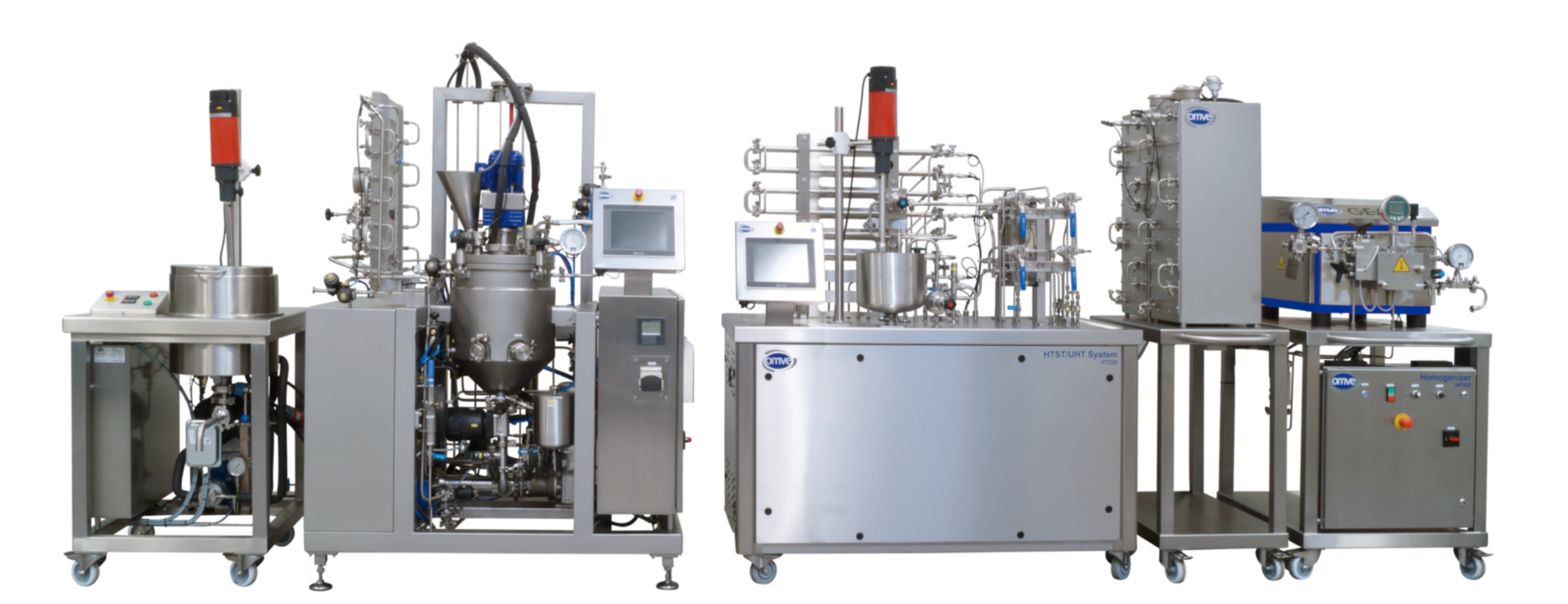

As nossas linhas de sistemas de tratamento térmico permitem pasteurização no recipiente, pasteurização e esterilização em linha e cozimento em lotes de uma vasta gama de produtos líquidos, começando por um lote com a dimensão mínima de um litro.

Conforme a viscosidade do produto e o processo que pretende reproduzir, podemos fornecer-lhe uma variedade de trocadores de calor e métodos diferentes, incluindo HTST e UHT.