Cost-Effective and Automated Homogenization

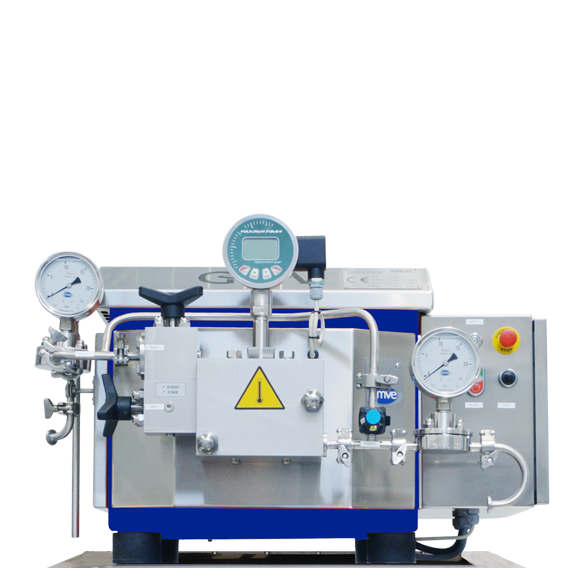

The HP102 In-line Homogenizer is a high-pressure system designed to operate continuously alongside OMVE’S HTST/UHT systems, allowing for the accurate simulation of production processes. This equipment improves the properties of liquid products, offering higher stability, prolonged shelf life, and a better mouthfeel for applications such as dairy and plant-based beverages. The system features a cost-effective construction and is designed to operate hygienically in-line without the need for pulsation dampers, which eliminates unwanted dead zones. With its high level of automation, the HP102 ensures deviation-free operation and can be seamlessly connected to the HT220 Basic or used as a standalone solution.