Remplissage aseptique avec décontamination automatique

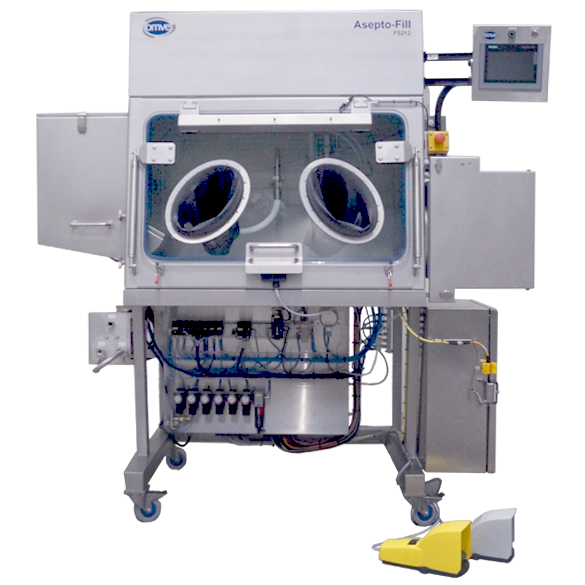

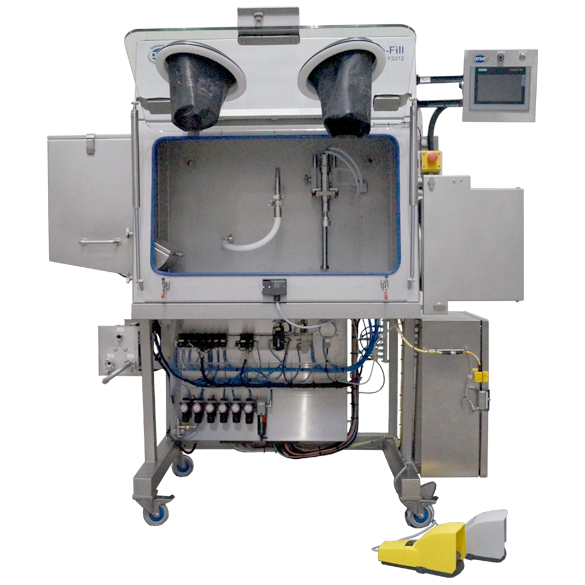

La demande en équipements de remplissage aseptique à froid pour les nutraceutiques, les boissons fonctionnelles et les alternatives pharmaceutiques à l’échelle du laboratoire est croissante. Adaptée aux marchés agroalimentaire et pharmaceutique, l’enceinte de remplissage aseptique FS213 combine la stérilisation en place (SIP) et la stérilisation chimique grâce au principe de l’isolateur et à un flux d’air stérile descendant. L’automatisation de la stérilisation chimique de la surface externe des flacons élimine les risques de contamination lors de leur transfert vers la machine de remplissage. Une enceinte de transfert de flacons, reliée à l’enceinte de remplissage, permet l’utilisation de conditionnements de différentes tailles et formes. Pendant la production, les deux enceintes sont entièrement conditionnées afin de prévenir les erreurs de manipulation.

L’option de débouchage, de remplissage et de fermeture semi-automatisée permet un remplissage à des cadences allant jusqu’à 100 L/h.