Flexible, modular, controlled

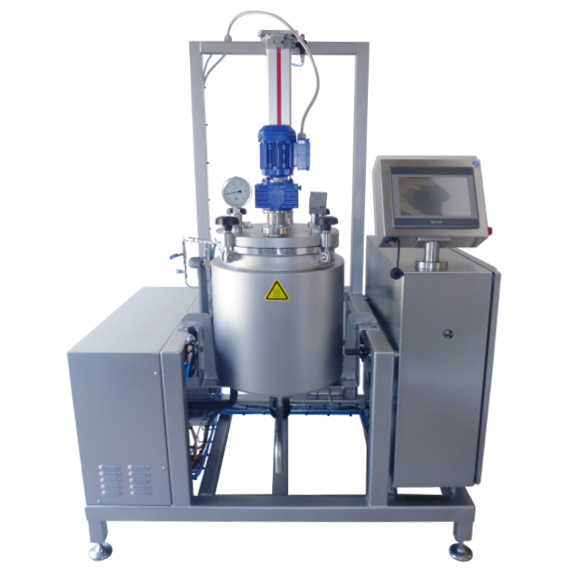

OMVE’s batch cookers, including our MPV350-BC unit, perform a range of batch food processes. All units can be centrally controlled via a touchscreen, where critical control points (CCPs) such as temperature and pressure are automatically controlled and monitored. After filling, set the double jacketed vessel to the required parameters before turning on the selected mixers.

Our batch pasteurizer and batch cooker systems are pressurized double jacketed process vessels offering automated temperature and pressure control. The double jacket can be heated with steam or electricity. Our batch cookers are typically equipped with a low-speed anchor agitator that includes scrapers, and optional low-, high-speed or high-shear mixers. Other popular options include a vacuum system for deaeration, and a cleaning in place (CIP) package. OMVE’s batch cookers are often used as a standalone system, though they can also be connected to our process equipment.

The OMVE batch cooker comes in a range of capacities, including 20L, 50L and 100L.