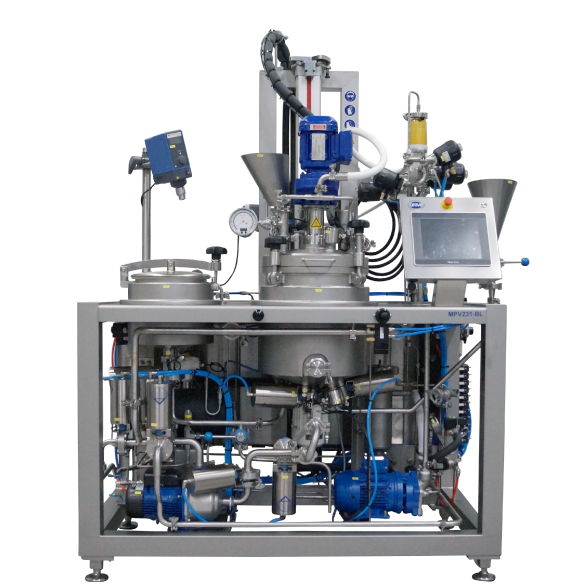

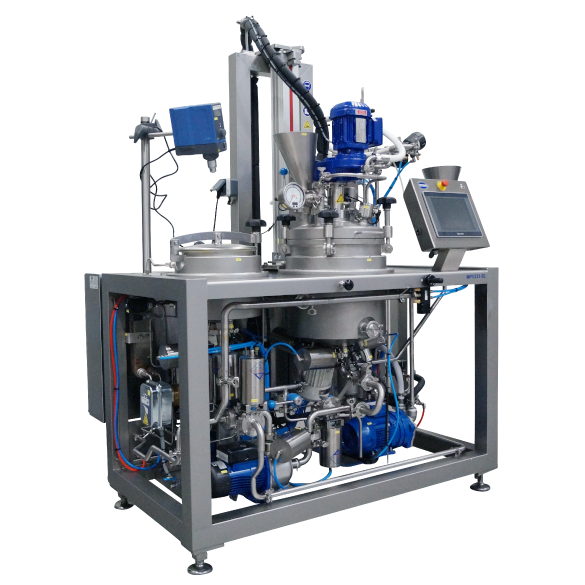

Comprehensive, versatile, compact

Combining ingredients correctly is a key step to formulating and scaling up new products. Inadequate mixing can even create lumps & fat separation. The ability to mix powders and liquids homogeneously is a critical aspect of product quality, safety, and shelf life.

With the MPV231EF, our cost-effective and time-saving system will enable you to easily create stable emulsions with the finest possible droplet size. The high level of automation ensures a reliable mixing process and guarantees that trial results can be reproduced every time. The unique size of only 20L batches and the flexibility of this mixing vessel makes it invaluable for any application lab and R&D center.