Safe, Smart and Ergonomic

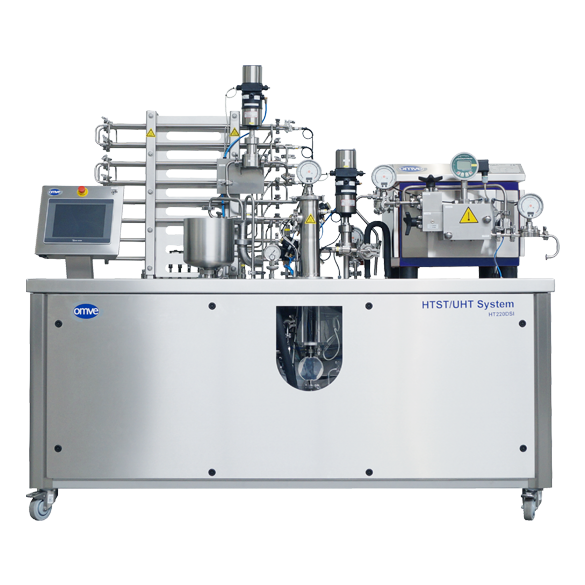

The OMVE HT220DSI system has been designed to process low & high acid products with direct and indirect heat treatment. This fully integrated system incorporates all features already offered by OMVE HT220 system. This system can easily be controlled by one operator.

The HT220DSI can be supplied with low or high automation to guarantee reproducibility of formulations, and to provide R&D technicians complete flexibility.

Food scientists can process heat-sensitive and complex applications using accurate amounts of steam to instantly heat and then flash cool the product. In addition, the HT220DSI system can be built using a variety of cooling and heating functions to enable food scientists, to perfect their recipes by meeting the right time-temperature processing conditions, while creating enough turbulence at low rates.

Food developers can prepare healthy organic, dairy or plant-based beverages, nutraceuticals, smoothies, baby food and other high viscous formulations, using indirect HTST/UHT via tubular heat exchanger or Direct UHT with steam injection, with optional inline homogenization in upstream mode and/or downstream mode (aseptic execution)

To maintain sanitary and/or hygienic capabilities, OMVE’s HT220DSI system comes with built in CIP and SIP technologies. For these reasons, OMVE’s HT220DSI system is an ideal system to scale up production.