Flexible, modular, future-proof

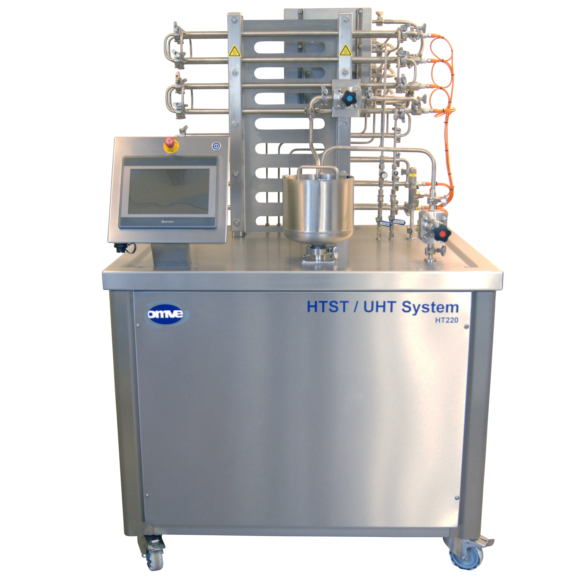

The HT220 system is highly versatile. It allows you to run a trial with a less than three liters of product, minimizing the amount of ingredient that is required, as well as the time required for preparation, set-up and processing. Moreover, the HT220 Lab UHT/HTST System helps improve R&D activity by allowing you to conduct a greater number of trials over the course of the day.

The HT220 series offers different levels of automation and configuration. The available heat treatment modules include the tubular heat exchanger, plate heat exchanger, scraped surface heat exchanger (SSHE).

When looking to replicate the industrial processes for heat-sensitive and other complex applications such as milk-replacement products, desserts, and creams, the HT220 series offers a steam injection module variation, called HT220DSI. Food developers find HT220DSI very user friendly as well as versatile because it allows them to process products with indirect heat treatment or by injecting them with steam.

The HT220 systems, can be integrated with an inline homogenizer and an inline deaerator. With the HT220 series, you can configure a pilot line with downstream equipment, including buffer tanks, fermentation tanks, and hygienic or aseptic fillers.

Our HT220 is available with a nominal capacity of 20L/h or 50L/h.