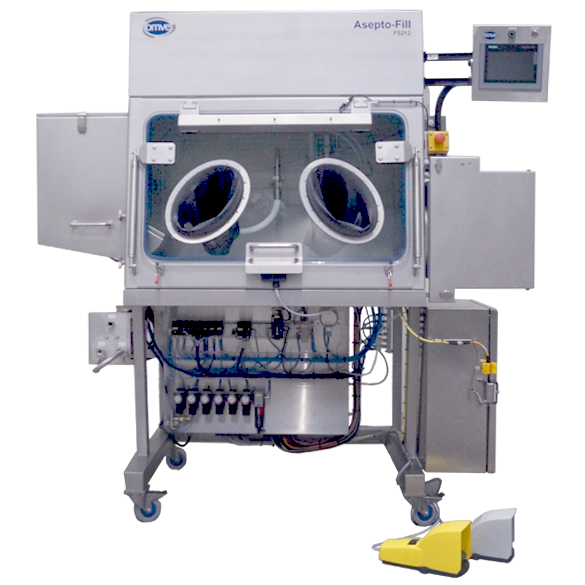

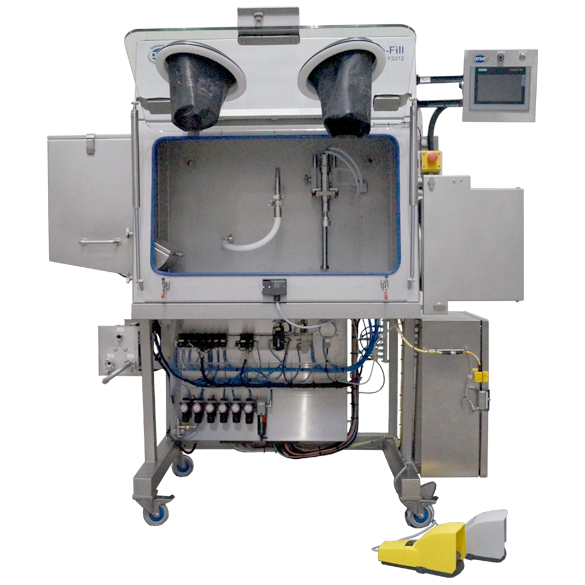

Aseptic Filling with Automatic Decontamination

There is a growing demand for cold aseptic filling equipment for nutraceuticals, functional beverages, and pharmaceutical alternatives on a laboratory scale. Suitable for both the food and pharma markets, the FS213 aseptic filling cabinet combines SIP and chemical sterilization using both the isolator principle and a down flow of sterile air. By automating the chemical sterilization of the outer surface of the bottles, risks of contamination when transferring the bottles into the filling are eliminated. A bottle transfer cabinet connected to the filling cabinet enables the use of various sizes & styles of packaging. During production both cabinets are fully conditioned to prevent operational errors.

The semi-automated un-capping filling and closing option enables filling at line capacities up to 100L/hr.